PSA nitrogen technology

Description

一、Description

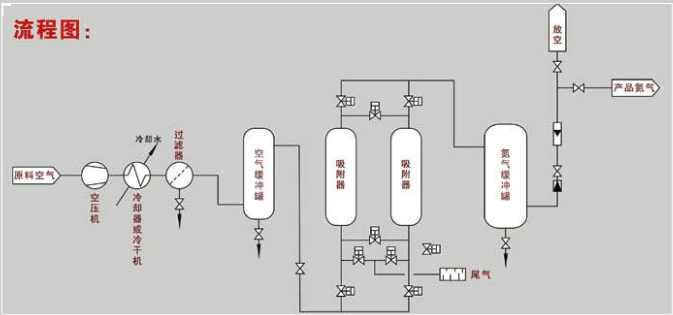

Pressure-variable adsorption nitrogen generator (PSA nitrogen generator for short) is a nitrogen generating equipment designed and manufactured according to pressure-variable adsorption technology. Usually two adsorption towers are connected in parallel, and the fully automatic control system strictly controls the time sequence according to specific programmable procedures, and alternately carries out pressure adsorption and decompression regeneration to complete the separation of nitrogen and oxygen, and obtain the required nitrogen gas with high purit

二、Technical features

1、Convenient and quick nitrogen production

Advanced technology, unique airflow distributor, make the airflow distribution more uniform, efficient use of carbon molecular sieve, can provide qualified nitrogen in about 20 minutes.

2、Easy to use

Compact equipment structure, the whole skid mounted, occupies a small area without infrastructure investment, less investment, the site only needs to connect to the power supply to produce nitrogen.

3、More economical than other nitrogen supply methods

PSA process is a simple method of nitrogen production, using air as raw material, energy consumption is only the power consumed by the air compressor, with low operating costs, low energy consumption, high efficiency and other advantages.

4、Mechanical and electrical integration design to achieve automatic operation

Imported PLC control fully automatic operation, nitrogen flow pressure purity adjustable and continuous display, can achieve unattended.

5、Technical index

Flow rate:5-1000Nm/h Purity:95%-99.9995% Dew point:≤-40℃ Pressure:≤0.8Mpa adjustable.

三、Application scope

Protective gas for metal heat treatment process, production gas for chemical industry and nitrogen filling and purification of all kinds of tanks and pipelines, production gas for rubber and plastic products, oxygen-exhausting and preserving packaging for food industry, purification and covering gas for beverage industry, nitrogen-exhausting and nitrogen-charging packaging and containers for pharmaceutical industry, and protective gas for electronic components and semiconductor production process in electronics industry. The purity, flow rate and pressure are stable and adjustable to meet the needs of different customers.

Flow Schematic

Cases

1. | Jinzhou Petrochemical Company | 200Nm3/h ambient 99.5% PSA |

2. | Qingdao Petrochemical Company | 300Nm3/h ambient 99.9% PSA |

3. | Qingdao Petrochemical Company | 50Nm3/h ambient 99.999% PSA+purity |

4. | Kunming Iron and Steel Company | 1200Nm3/h ambient 99.999% PSA+purity |

5. | Handan Iron and Steel Company | 400Nm3/h ambient 99.999% PSA+purity |

6. | Yantai Juli TDI Co. | 800Nm3/h ambient 99.9% PSA |

7. | Baling Petrochemical Company | 1000Nm3/h Cyclohexanone off-gas 99.99% VSA |

8. | Shandong Hongye Chemical Co. | 2X1500Nm3/h ambient 99.9% PSA |

9. | Zhanjiang Petrochemical Co. | 1000Nm3/h ambient 99.99% refined |