Variable Pressure Adsorption (VPA) CO2 removal process is widely used in ammonia, methanol, butanol decarbonisation units and urea, soda ash, industrial CO2 purification CO2 units as well as chi gas and CO2-containing tail gas recovery units due to its high degree of automation, convenient adjustment of removal accuracy, wide range of application, low energy consumption, and other features.

Nitrogen generator by pressure swing adsorption (PSA nitrogen generator for short) is a nitrogen generation equipment designed and manufactured according to the gas separation theory of pressure swing adsorption.

Pressure-variable adsorption nitrogen generator (PSA nitrogen generator for short) is a nitrogen generating equipment designed and manufactured according to pressure-variable adsorption technology.

After the vinyl chloride tail gas is divided into liquids by the liquid separation tank, there are still a large amount of vinyl chloride and acetylene, and the vinyl chloride and acetylene are concentrated and recovered by the adsorption method, which is of high economic value.

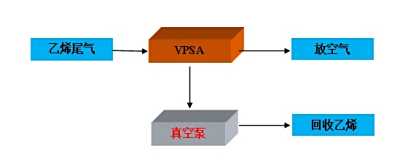

In recent years, with the enhancement of people's awareness of environmental protection, the international and domestic environmental protection requirements for petrochemical plants, as well as from the waste recycling and reuse, reduce production costs, and create higher economic benefits for the enterprise on the consideration of the process of ethylene, propylene plant tail gas recovery have greater social and economic benefits.

Ionic liquid flue gas desulphurisation technology is mainly used for the treatment and resource utilisation of sulphur dioxide in flue gas and other industrial waste gases. This technology can recover sulphur dioxide with purity as high as 99.5% for the production of chemical products such as sulphuric acid, liquid SO2 or sulphur at the same time of efficient desulphurisation, thus realising the resourceful use of sulphur pollutants.

Wet decarbonisation is a widely used decarbonisation process with low energy consumption and is widely used to remove CO2 and H2S from ammonia, methanol feedstock gas, refinery gas, city gas and natural.

PSA method of biogas concentration is to use adsorbent to separate methane, carbon dioxide and nitrogen in biogas, so as to achieve the purpose of methane concentration.

Oil tanks, loading emission gas, petrochemical and chemical production of VOC-containing tailpipe gas, the first variable pressure adsorption concentration, and then condensation recovery process, so as to meet the requirements of environmental protection emissions, but also to recover part of the organic matter.

In industrial hydrogen purification by pressure swing adsorption (PSA), the adsorbents generally adsorb the easily adsorbed components out of the gas mixture at ambient temperature and high pressure, while the not easily adsorbed components (such as hydrogen) flow out from one end of the bed as the product

To produce LNG from natural gas, the CO2, H2S and other components in natural gas are firstly absorbed by MDEA solution, and the unabsorbed purified gas is dried after liquid separation and then put into the cold box to produce LNG.

The company's proprietary technology developed for low concentration gas, after fully analysing the nature of the raw gas, adopts variable pressure adsorption under micro-pressure conditions to separate CH4 and N2/O2.

Purification of carbon monoxide from mixtures containing carbon monoxide, hydrogen, nitrogen, methane, carbon dioxide and other components using the variable pressure adsorption process.