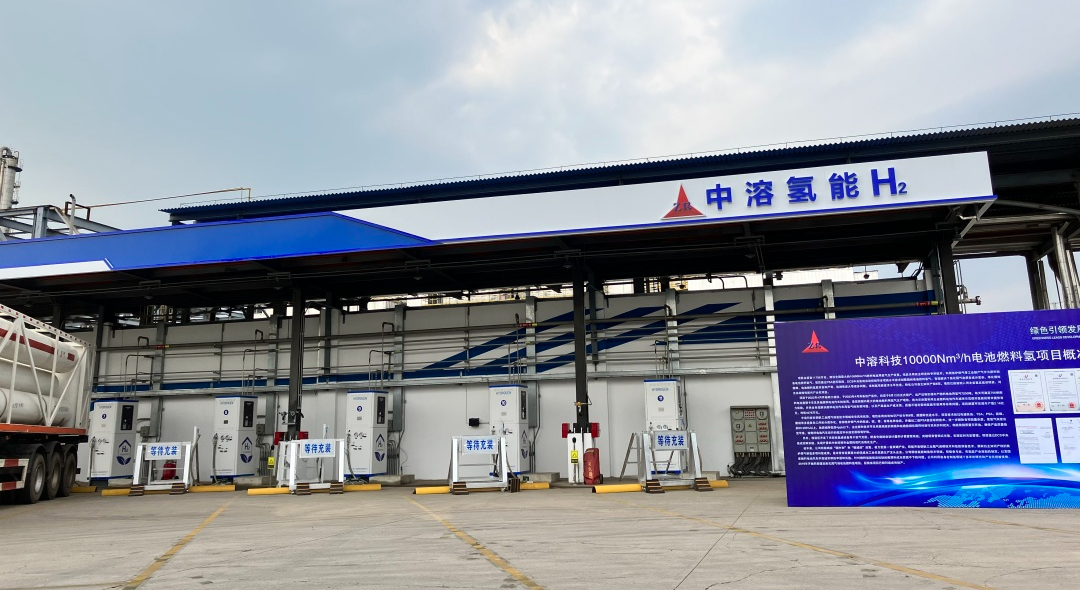

The 10,000 Nm3/h battery fuel hydrogen project with the largest single capacity in China constructed by Yizhi Technology was put into production in Qian'an, Hebei!

The 10,000 Nm3/h hydrogen project of Tangshan Zhongsol Technology Co., Ltd. has been completed and put into production after a successful one-time start-up. After the project reaches production, it will achieve an annual output of 7200 tonnes of hydrogen for fuel cells, which can satisfy the use of 700 fuel cell heavy-duty trucks and other fuel cell vehicles every day, and help reduce CO2 emissions by 82,000 tonnes per year.

The 10,000 Nm3/h hydrogen production project of Tangshan Zhongsol Technology Co., Ltd. was completed and put into production after a successful one-time drive. After the project reaches production, it will achieve an annual output of 7200 tonnes of hydrogen for fuel cells, which can meet the use of 700 fuel cell heavy-duty trucks and other fuel cell vehicles every day, and help reduce carbon dioxide emissions by over 82,000 tonnes per year.

The hydrogen project is designed and installed by Chengdu Yizhi Technology Co., Ltd. and utilises the product hydrogen from the existing coke oven gas hydrogen plant in the plant as the raw material for purification, compression and charging. The scale of production is 10,000 Nm3/h hydrogen plant, and the product specification should meet the standards of high purity hydrogen and hydrogen for fuel cell, of which CO≤0.2ppm and total sulfur≤4ppb.

The PSA purification plant adopts our self-developed adsorbent for purifying high purity hydrogen, which can meet both the hydrogen standard for fuel cell and 99.999% high purity hydrogen, and the two purities can be freely switched to meet the owner's requirement of adjusting the product specifications according to the market situation. Effectively solve the coking tail gas impurities, complex composition, purification and purification difficulties, high requirements for battery fuel hydrogen, testing difficulties and many other problems, and adsorbent life of up to 20 years, investment savings, low energy consumption.

At the same time, the implementation of the project throughout the process of each link, our company uses high-precision offline and online testing instruments for real-time control, thoroughly achieve quality without dead ends, to ensure energy saving and environmental protection, product quality and stability, device operation is safe and reliable. In addition, our company also developed the charging column integrated equipment for hydrogen charging, equipped with advanced automatic metering and billing management system, which breaks through the existing tube and valve charging and realises real-time charging management.

After the hydrogen project is completed and reaches production, Zhongsol Technology will have a production capacity of no less than 7,200 tonnes/year of fuel hydrogen, and will become the largest producer and supplier of hydrogen for hydrogen fuel cell vehicles in the Beijing-Tianjin-Hebei region.

Carbon emissions are widespread in energy, industry, transport and all aspects of social and economic life, and reducing carbon emissions is the key to achieving the "double carbon" goal. As a clean and efficient secondary energy source, promoting the use of hydrogen is an important way to address climate change, implement the concept of green development, and accelerate industrial transformation and upgrading. In the future, Yizhi Technology and Huaxi Chemical will continue to take the lead in innovative technology, make integrated engineering solutions, and provide various gas separation engineering technologies to meet the needs of enterprises for low energy consumption, low emissions and low pollution, and make positive contributions to accelerating the construction of a "clean, low-carbon, safe and efficient" energy system, promoting the green transformation of energy and the high-quality development of the economy. To accelerate the construction of a "clean, low-carbon, safe and efficient" energy system, promote the green transformation of energy and high-quality economic development to make positive contributions.

Chengdu Yizhi Technology Co., Ltd. is a chemical research and engineering design and construction unit integrating scientific research, design, technical service, product development and production. The company is mainly engaged in the separation and purification of various industrial gases, and possesses Class A design qualification for chemical engineering in chemical, petrochemical and pharmaceutical industries and Class A qualification for design of environmental engineering (air pollution prevention and control engineering).