Variable Pressure Adsorption Nitrogen Technology: Principles, Applications and Development

Nitrogen, as one of the most abundant gases on earth, is widely used in industrial production, medical treatment, food packaging and many other fields. Variable pressure adsorption nitrogen technology, as an efficient and economical gas separation method, has attracted much attention in recent years.

The basic principle of pressure swing adsorption (PSA)

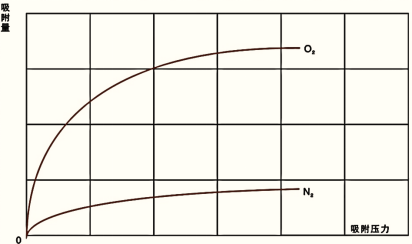

Pressure swing adsorption (PSA) is a separation technology based on the selective adsorption of gas components by solid adsorbents. In the process of nitrogen production, the difference in the adsorption capacity of adsorbent (such as carbon molecular sieve or zeolite) on oxygen and nitrogen is mainly utilised to realise the separation of gases through periodic pressure changes. Specifically, when the adsorption bed is adsorbed at a higher pressure, oxygen is more easily adsorbed by the adsorbent due to its smaller molecular diameter and faster diffusion rate, while nitrogen is relatively less adsorbed due to its larger molecular diameter and slower diffusion rate. Subsequently, the pressure of the adsorption bed is reduced, and the adsorbed oxygen is desorbed from the adsorbent, thus realising the separation of oxygen and nitrogen. Through the alternating operation of multiple adsorption beds, high purity nitrogen can be continuously produced, with a purity of up to: 98%~99.9%.

▲ Oxygen and nitrogen adsorption curve diagram

Application fields of variable pressure adsorption of nitrogen

1. Industrial production: In petrochemical, electronics, metallurgy and other industries, high-purity nitrogen is used as protective atmosphere, reaction medium or carrier gas. Variable pressure adsorption nitrogen technology can meet the requirements of these industries for nitrogen purity, flow and stability.

2. Healthcare: In the medical field, nitrogen is used for anaesthesia, respiratory treatment and protection of drugs and biological samples. Variable pressure adsorption nitrogen equipment is particularly suitable for on-site nitrogen production in medical institutions due to its compact and efficient features.

3. Food Packaging: Nitrogen as an inert gas is used in food packaging to exclude oxygen and prevent oxidation and deterioration of food. Variable pressure adsorption nitrogen technology provides an economical and reliable source of nitrogen for the food industry.

4. Other fields: In addition, in scientific research, environmental protection, aerospace and other fields, variable pressure adsorption nitrogen technology also plays an important role.

Advantages and challenges of variable pressure adsorption nitrogen technology

Variable pressure adsorption nitrogen technology has the advantages of low energy consumption, simple operation, small equipment footprint and fast return on investment. Compared with the traditional deep-cooling method, VASN does not require the use of low-temperature equipment, so the operating cost is lower. In addition, VAS nitrogen equipment starts up quickly and can reach a stable operating state in a short time, which is especially suitable for intermittent nitrogen use or occasions with large fluctuations in nitrogen demand.

However, VARNAM technology also faces some challenges. Firstly, the selection and performance of adsorbent directly affect the effect and cost of nitrogen production. At present, there are many kinds of adsorbents on the market with different performances, so how to choose a suitable adsorbent is a key issue in the process of nitrogen production. Secondly, the waste gas (mainly oxygen-enriched air) generated in the process of variable pressure adsorption nitrogen production needs to be handled properly to avoid environmental pollution and safety hazards. Thirdly, with the improvement of nitrogen purity requirements, the difficulty and cost of VAS nitrogen technology will increase accordingly.

Development trend of variable pressure adsorption nitrogen technology

With the progress of science and technology and the change of market demand, the variable pressure adsorption nitrogen technology is developing in the direction of more efficient, more environmentally friendly and more intelligent. On the one hand, researchers are committed to developing new high-performance adsorbents to improve the efficiency and purity of nitrogen production; on the other hand, through the optimisation of the process and equipment design, energy consumption and exhaust gas emissions are reduced to achieve green production. In addition, combining VARA technology with modern information technology such as Internet of Things and big data to achieve remote monitoring and intelligent management of equipment is also an important trend for future development.

Variable pressure adsorption nitrogen technology is widely used in many fields. Facing the challenges and opportunities in the future, we believe that VASN technology will continue to innovate and improve, bringing more convenience and value to industrial production and human life.