离子液脱硫技术处理克劳斯尾气新技术

离子液对二氧化硫的吸收能力非常强,溶剂循环量只有MDEA溶剂的1/15~1/5,公用工程消耗比MDEA溶剂吸收和再生低得多

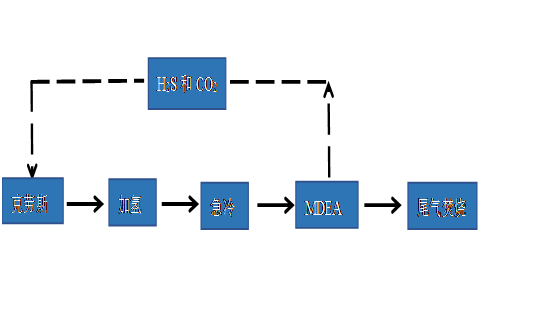

1.1 常规工艺

“克劳斯制硫+加氢还原吸收尾气处理”工艺过程如附图1

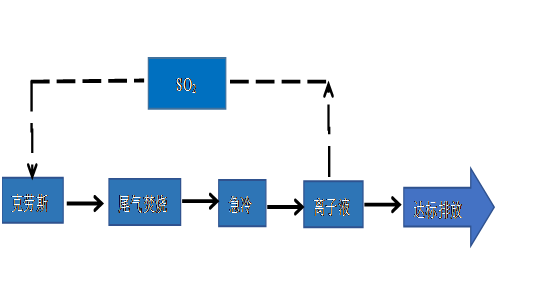

1.2离子液脱硫技术处理克劳斯尾气新工艺

“克劳斯制硫+离子液吸收尾气处理”工艺过程如附图2

1.3 Comparison of process description

1) The regenerated acid gas returned to Klaus Sulphur by solvent regeneration in the process of "Klaus Sulphur + Hydrogen Reduction Absorption Tail Gas Treatment" is H2S; the regenerated acid gas returned to Klaus Sulphur by ionic liquid regeneration in the process of "Klaus Sulphur + Ionic Liquid Absorption Tail Gas Treatment" is SO2. The regenerated acid gas in the process of "Klaus Sulphur + Ion Liquid Absorption Tail Gas Treatment" is SO2.

2) There is no tail gas hydrogenation and reduction process in the process of "Klaus Sulphur + Ion Liquid Absorption Tail Gas Treatment".

1.4 Technical advantages of the new process

1) There is no need for Klaus tail gas hydrogenation and reduction process, and no consumption of hydrogen source; construction investment and operation costs are lower.

(2) The absorption capacity of ionic liquid on sulfur dioxide is very strong, the solvent cycle volume is only 1/15~1/5 of MDEA solvent, the consumption of public works is much lower than MDEA solvent absorption and regeneration, the energy consumption is lower, and there is an advantage in the production cost.

(3) The concentration of sulfur dioxide in the purified gas after ionic liquid absorption can be guaranteed to be no more than 50mg/Nm3, and the sulfur dioxide yield in the tail gas can reach more than 99.5%. If you want to further reduce the concentration of sulphur dioxide in the exhaust gas, as long as the operating parameters are moderately adjusted, no need to modify the device, and the production cost will not increase.

(4) The ionic liquid only absorbs sulphur dioxide, there is no problem of co-absorption of CO2 by MDEA solvent, and it has the incomparable advantage of MDEA solvent absorption for the treatment of acid gas of coal chemical industry which contains very high CO2. It eliminates the side effects brought by a large amount of CO2 circulation, and the equipment size can be reduced with lower construction investment.