Achievements

HOME >>

Achievements

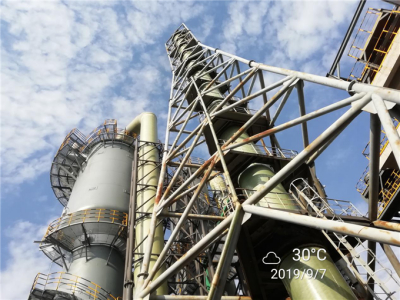

A plant in Shaanxi sulfuric acid tail gas desulphurisation system new desalination unit

因原设计漏缺脱盐装置,脱硫系统运行后一定时间后脱硫溶剂逐步恶化直至报废,业主采购我公司离子液替换原其他品牌脱硫剂,并新增脱盐撬装装置维持脱硫主系统稳定运行

2024-03-01

Anhui a plant renewable lead oxygen-rich side-blowing melting furnace flue gas + side-blowing reduction furnace flue gas + refined acid a turn a suction sulphuric acid tail gas mixed flue gas ionic liquid desulphurisation device

low-temperature desulphurisation and denitrification integration, double electric mist, emission tail gas depth whitening without plume;

2024-03-01

New desulphurisation plant for anode furnace flue gas plus water quenching flue gas in a plant in Guangxi, China

Normal operation tail gas is kept at 8~15mg/Nm3 for a long time, and 50% steam is saved after opening MVR system.

2024-03-01

Ion Liquid Desulphurisation Device for Flue Gas of Reduction Furnace and Flue Gas of Fuming Furnace at a Plant in Inner Mongolia

Tail gas indicator limited to the limit within the venture, discharge tail gas depth de-whitening, no smoke plume in summer;

2024-03-01

Ionic liquid desulphurisation device for sulphuric acid tail gas of a plant in Shandong, China

ultra-low emission, no plume in the tail gas, one turn and one suction supporting ionic liquid desulphurisation process are mature and reliable, the system runs easily and smoothly, it is a very ideal combination with;

2024-03-01

Latest Articles

CONTACT

TEL:+86 028-86198011

E-mail:hxhg@hxhg.cn

FAX:028-86198015

ADD:13/F, Building 1, Caiji International, No. 595 Jinzhou Road, Jinniu District, Chengdu, China

WeChat

Copyright © 2023-2024 Chengdu Yizhi Technology Co.Ltd